animal feed pellet line

Intensive feedstuff production for different animal is an urgent needs owing to the prosperous breeding industry. Over ten years’ feed pelletizing solutions and experiences, KMEC provides perfect projects for any scale animal feed pellet line. Furthermore, the feedstuff pellet mill plant can make various feed pellets for chicken, ducks, cattle, pigs, sheep, rabbits etc. And the whole production line is controlled by the automatic PLC. Therefore, it is easy to operate and save the labor cost.

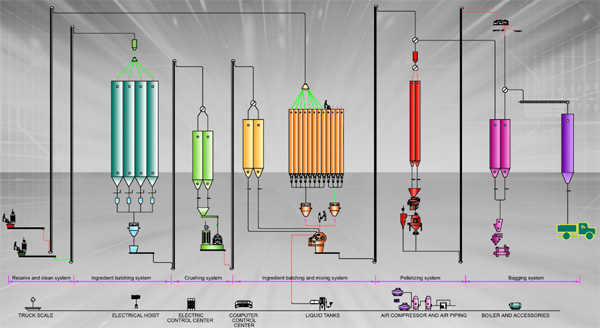

Flow Chart of Animal Feed Pellet Line

In our feed pelletizing solutions, we wll provide the total projects planning including civil engineering, steel construction, storage system, feed pelletizing machine, automatic packing, automatic PLC control system. KMEC has much more experiences on feedstuff pellet mill plant. So KMEC is a very reliable manufacturer and supplier of animal feed pellet plant. In addition, we supply different capacity animall feed pellet lines depending on customers different needs. Our planning team will design a perfect turnkey project for you about feedstuff pellet mill plant.

Advantages of Feedstuff Pellets:

★Decreased ingredient segregation and feed wastage.

★It is easy to store and transport

★The feedstuff pellets improves palatability for animals.

★Reduced selective feeding

★Destruction of pathogenic organisms

Feed Production Processing

Raw Materials for Animal Feed Pellet Line

A wide range of raw materials like corn, wheat bran, paddy, soybean meal, paddy rice, sorghum etc..

Related Equipments for Animal Feed Pellet Line

|

The hammer mill is an important equipment for the raw material grinding process. The hammer mill can grind the raw materials ingredients into the required size. It is suitable for small or medium sized feedstuff pellet mill plant. While if you manage a large scale feedstuff pelletizing factory, the water drop hammer mill is an ideal choice. |

|

Mixing is one of necessary processing in animal feed pellet line. Proper mixing will lead to increase diet uniformity and improve the feedstuff quality. We will provide two kinds of high efficiency feed mixers: twin shaft mixer for particle materials and screw belt mixer for powdered materials. Both of them are equipped with atomizing spraying system to add needed liquids which can improve feed pellets quality. |

|

Feed pelletizing machine is the key feed equipment for the animal feed pellet line. The feed pelletizing machine is the ring die design which is broadly used to large capacity feed pellets production. If you have another questions about feed pellets production requirements like capacity or scale, please send e-mail to us for more support and guidance. |

|

Getting out of the feed pelletizing machine, the feed pellets with high temperature and large moist need cooling by counterflow cooler. The these feed pellets can be crushed, screened or packed. Through the cooler, the feed pellets are decreased the temperature and moisture for next processing. |

|

Because different animal such as poultry, cattle and pig feed pellets are with different sizes. Some big feed pellets should be crushed into small particles. The feed pellet crumbler is the right equipment for the feed pellets crushing. The double roll feed pellet crumbler is suitable for crushing animal feeds like poultry, pig and cattle feed etc.. |

|

By feed pellet crumbler, there may be some powder in the pellet feed. The rotary grading sieve is used to screen and grade the feed pellets. After this processing, you can get qualified feedstuff pellets without powder. |

|

In order to pack for storing, transporting and selling, automatic packing machine can weigh and pack the feedstuff pellets automatically with high accuracy. |

Our Feedstuff Pellet Mill Plant Installed Abroad:

.G1 Solutions Inc.; CA, USA (90000 ton/year feed mill, KMPM42)

.L.T.D. Caucasus Agro International; Georgia (30000 ton/year feed mill, KMPM35)

.Alhassan Farms; Ghana (30000 ton/year poultry feed mill, KMPM35)

.Ngawi K.A.B.; East Jawa, Indonesia (50000 ton/year cattle feed mill)

.Hum Huat (Sarawak) Sdn. Bhd.; Malaysia (6 ton/year mash feed mill)

.Al-Taqua Co.; Egypt (30000 ton/year poultry feed mill)

.PT Jadi Mas; Indonesia (30000 ton/year compost pellet mill)

.Emman Farming Enterprises Limited; Zambia (90000 ton/year poultry feed mill)

Our Feedstuff Pellet Mill Plant Installed Domestically:

.Feed processing line of Liuhe Group in Tai’an Lelin (180,000 tons/year)

.Feed processing line of Liuhe Group in Boxing (120,000 tons/year)

.Jinzhou Feed Co., Ltd of Liuhe Group (60,000 tons/year)

.Jilin Feed Co., Ltd of Liuhe Group (90,000 tons/year)

.Yingwei Group (Belgium & Henan) Co., Ltd, feed processing line (180,000 tons/year)

.Shandong Weizun Feed Co., Ltd (180,000 tons/year)

.Linyi Feed Factory of Shandong Mengfa Feed Group (60,000 tons/year)

.Henan Dade Aquatic Feed Factory (Zhengzhou) (120,000 tons/year)

.Shandong Yishui Zhengxiang Feed Co., Ltd (60,000 tons/year)

.Henan Longbao Feed Co., Ltd (120,000 tons/year)

.Weishi Lvfeng Feed Co., Ltd (60,000 tons/year)

.Shangqiu Huipu Feed Co., Ltd (60,000 tons/year)

.Tianjin Tiaozhan Feed Co., Ltd (90,000 tons/year)

.Luoyang Feed Co., Ltd (Zhengbang Group) (90,000 tons/year)